What works

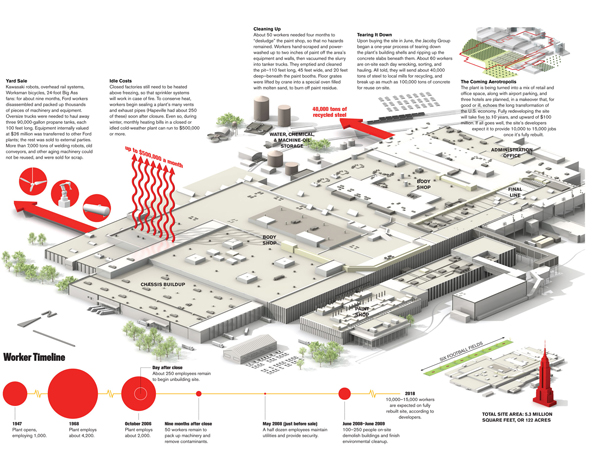

This diagram of the closure of a Ford plant identifies both physical and temporal processes that a marvel of modern manufacturing has to undergo in order to cease production in a rational way. Environmental damage has to be mitigated – the paint shop is especially toxic and it seems to take workers years to handle that. [Let me register my vote here for automotive paneling that can be modified without paint or other dreadfully toxic processes. Surely, there has to be a better way. Sandblasting?]

The diagram is very smart. It maintains the size of the Ford plant – the thing takes up most of the visual space. Clearly, it could have taken up less space and given over more space to various explanatory text blocks and additional-information diagrams in sidebars, but I think that approach would have diminished the gargantuan nature of both the plant itself and the processes of shutting it down.

Second, the integration of a timeline measured by number of workers employed is just the perfect layer of information to pull the rest of the text-boxes together as a narrative. The timeline makes the whole graphic complete.

Third, I don’t mind the length of the text in the text blocks. It seems about right to me.

What needs work

I could have used some additional information about the relative uniqueness or typical-ness of an automotive plant closure (or even various elements of the plant closure process). The New York Times article Developers Revive Closed Auto Plants notes that about half of the nation’s 263 closed auto plants have been revived one way or another. In one case, an old Ford transmission factory now houses a community college with a 4-year nursing program on one corner, an aluminum scrap processor on another, a mobile facilities manufacturer in a third location, but is still more than half vacant. I was curious while looking at this graphic: Would Ford have had to go through the same kind of process with a transmission factory (they don’t paint transmissions so it seems it should have been easier in that regard)? When a plant is going to be repurposed, does Ford still have to do all the same ‘closing time’ activities or do those become the responsibilities of the new owner? Is that a negotiable term?

While a graphic would have been hard-pressed to answer all of those questions, I was hoping it would be able to at least address the idea that plants are both closing altogether and being repurposed – two related but not synonymous occurrences. In some places where the plants are closing, municipalities demand that their former owners take them down to slabs under the assumption that a slab is more appealing to a new owner than a facility that may need to be torn down and rebuilt.

Overall, I think the graphic is successful but could be better with more contextual information. I know some of that was in the article, but I am only reviewing the graphic, which I think should be able to stand alone.

References

Peck, Don. (April 2009) Disassembly Line. The Atlantic.

Christie, Bryan. (2009) Disassembly Line [information graphic]. The Atlantic.